Hoffman Weber Scores NARI Contractor of the Year Honors for Exterior Facelift

by Matt McDaniel, on November 25, 2015

Hoffman Weber Construction entered the National Association of the Remodeling Industry’s annual Minnesota Contractor of the Year (CotY) competition last month and scored gold on its first attempt.

Project Manager Philip Hide accepted the CotY trophy for the best Residential Exterior <$100,000 at the association’s Black Tie/Red Carpet event at the Millennium Minneapolis Hotel. The exterior facelift was completed at the Hopkins home of Barry and Lisa Zelickson.

The Hoffman Weber project was one of 73 top Minnesota contractors that entered in 32 remodeling & landscaping categories. Judges from the Milwaukee NARI chapter rated the project on meeting clients’ needs, aesthetic and functional improvements, craftsmanship, innovation and degree of difficulty.

Aesthetic Enhancements

The existing T1-11 plywood siding looked plain, dated and cheap, and the entry disappeared in the pivot between the house and the long garage. The home screamed for architectural details and something that would make the entry more welcoming.

A dark stained, solid wood BayerBuilt door with matching sidelite adds rich character to the entry. They now are complemented by Clopay Coachman Collection garage doors.

The Environmental Stoneworks knee walls are hand-built and mortared stone by stone for authentic looking corners and a truly random pattern that a panelized stone facade could not achieve.

Custom trimmed new-construction Marvin windows feature site-crafted extension sills, crowned tops, beveled bottoms and hand-built shutters.

A new Owens Corning Duration shingle roof and seamless gutters complete the total transformation.

Functional Improvements

To keep surfaces durable and low maintenance and retain the wood look, prefinished James Hardie Custom Color siding, trim and soffits were used throughout the project.

Insultex insulated housewrap added R-6 insulation value to the original, 2x4-framed walls to improve comfort and conserve energy.

New seamless gutters with extended downspouts prevent rainwater and snowmelt from gathering around the foundation.

Prefinished, color-matched aluminum flashing above the knee wall capstones will never peel or streak the stone like galvanized flashing.

Superior Craftsmanship

To provide peace of mind for these highly engaged customers, Hoffman had the James Hardie rep do an on-site consult to specify every aspect of the installation and followed them carefully.

Where shakes come together at outside corners each course is hand trimmed to match the opposing taper without corner boards.

Prefinished flashing along the knee-wall capstones are site bent to provide discrete yet code-approved weatherproofing.

Innovation & Overcoming Obstacles

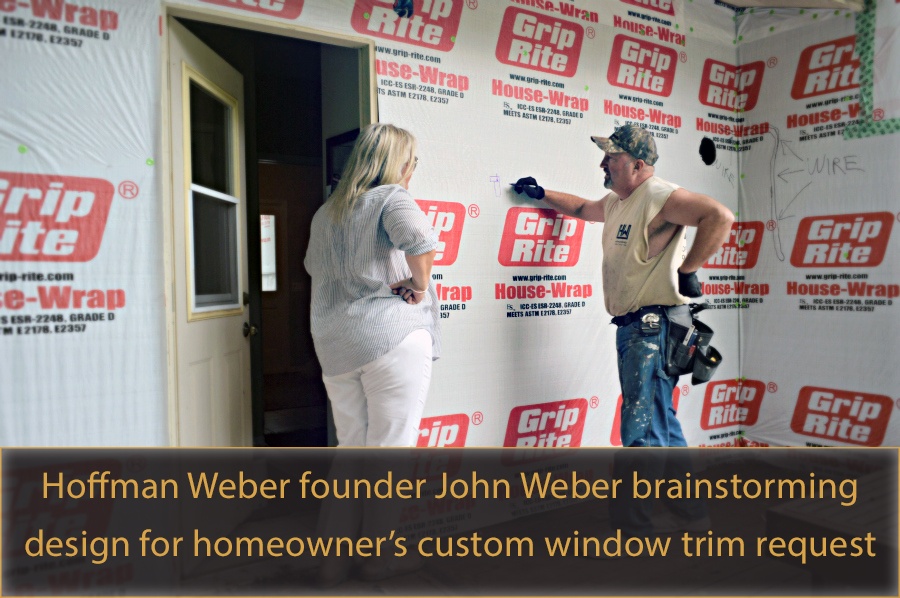

These clients knew what they liked when they saw it, but not necessarily until then. Color renderings wouldn’t do, so the contractor obliged with multiple prototypes of windowsill extensions, window trim and shutters until the precise look was achieved.

HW substituted prefinished, pre-formed LP SmartSide outside corners where the James Hardie lap siding meets because Hardie doesn’t offer preformed corners. Hardie specified that the ends of the drip edge flashing had to be caulked above the vertical trim, but the clients didn’t like how it visually elongated the affected shakes. The contractor substituted clear silicone caulk to their satisfaction.

CotY judges praised the Hoffman Weber project

CotY judges wrote: “The hand cut mitered corners are a great feature. This takes a lot of time and experience to achieve. I like that the contractor used all the same Hardie Board product throughout the project instead of inter-mixing, aluminum wrap, LP, etc. Beautiful transformation. The arched window trim and apron below the windows really make the design stand out.”